Born in the 1970s, Ethernet technology has continually evolved in order to meet the never-ending requirement for faster rates of data transmission. Through this ongoing evolution, it has matured into the foremost technology standard for local area networks (LANs) as newer, higher performing iterations, such as 1 Gigabit Ethernet and 10 Gigabit Ethernet. There is a variety of types of cables available for making Ethernet connections at speeds of 1 Gigabit and 10 Gigabit per second. This paper provides a brief introduction to these two types of high speed Ethernet cabling solution, 1 Gigabit Ethernet cabling and 10 Gigabit Ethernet cabling.

1 Gigabit Ethernet Cabling

When planning 1 Gigabit Ethernet cabling infrastructure, generally you have two choices: fiber optic or copper. Both offer superior data transmission. From the aspects of fiber cabling choices and copper cabling choices, solutions to 1 Gigabit Ethernet cabling are introduced as follows.

Fiber Cabling Choices

There are two common types of fiber cable available for 1 Gigabit Ethernet, single mode and multi-mode. Both cables provide high bandwidth at high speeds. There are a few other possibilities for range, mode, and wavelength, but the following two are predominate.

- Short Range: SR—for connections of up to 550 meters in length.

- Long Range: LR—for connections of up to 10 KM in length.

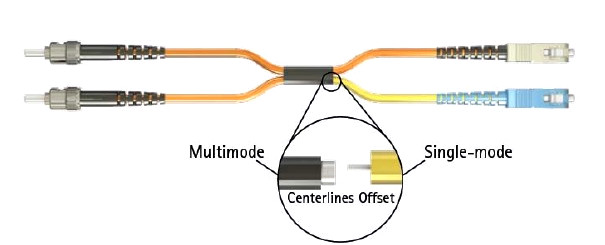

Fiber optic cable itself and connectors are used for fiber cabling. There are multiple choices for cable type and connector type. Multi-mode fibers and single mode fibers require different connectors. And optical fiber connections are constructed with a combination of a transceiver. The transceiver accepts digital signals from the Ethernet device and converts them to optical signals for transmission over the fiber. SFP (small form factor pluggable transceiver) is the most common type of transceiver used in 1 Gigabit Ethernet connections. The following is a picture of SFP transceiver modules.

Copper Cabling Choices

For 1 Gigabit Ethernet cabling, category 5 cable, commonly referred to as cat5, is a common choice. The cable standard provides performance of up to 100 MHz and is suitable for Gigabit Ethernet. Most cat5 cables are unshielded twisted pair cables, relying on the balanced line twisted pair design and differential signaling for noise rejection. Cat5e, an enhanced version of the category 5 specification was introduced several years ago. Cables of up to 100 meters in length can be used. RJ45 copper SFP transceiver module (Mini-GBIC) is built to offer a cost-effective way to add, replace or upgrade a copper Ethernet port on your networking equipment.

10 Gigabit Ethernet Cabling

10 Gigabit Ethernet cabling is very similar to 1 Gigabit Ethernet cabling. Solutions to 10 Gigabit Ethernet cabling are also introduced in fiber cabling choices and copper cabling choices.

Fiber Cabling Choices

For 10 Gigabit Ethernet cabling, the fiber options are very similar to 1 Gigabit Ethernet cabling. But the range is less due to the higher speed. In general, there are three distance ranges.

- Short Range: SR—for connections of up to 300 meters in length.

- Long Range: LR—for connections of up to 2,000 meters in length.

- Extended Range: ER—for connections of up to 10,000 meters (10 KM) in length.

The transceivers for 10 Gigabit Ethernet cabling are somewhat different. XFP or SFP+ transceivers are used to connect these 10 Gigabit Ethernet cables. The connector type itself defines the mechanical specifications of the fiber-to-transceiver interface. Thus one could have an XFP transceiver on one end of a 10 Gigabit fiber cable and an SFP+ transceiver on the other end. As long as the cable type and connector type match there is no problem. The following is a picture of XFP transceiver module.

Copper Cabling Choices

As switching standards mature and copper cabling standards catch up, the use of copper cabling for 10GbE is becoming more common. Currently, there are two different copper cabling technologies for 10 Gigabit Ethernet, each with different price and performance capabilities.

10GBase-CX4, published in 2004, was the first 10 Gigabit Ethernet copper standard. CX4 was relatively economical and allowed for very low latency. It uses a coaxial copper cable and can support cable lengths of up to 15 meters. Its disadvantage was a too-large form factor for high density port counts in aggregation switches.

10GBase-T was released in 2006 to run 10 Gigabit Ethernet over cat6a and cat7 copper cabling up to 100 meters. While promising, 10GBase-T still needs technology improvements to lower its cost, power consumption, and latency. Like copper cabling choices for 1 Gigabit Ethernet, 10GBase-T still uses RJ45 copper transceiver to provide reliable connections.

Just as there are many manifestations of 1 Gigabit Ethernet and 10 Gigabit Ethernet standards to suit various networking environments, there are also many copper and fiber cabling technologies to support them. Companies must have a solid understanding of not only their environment and need, but also the different standards and cabling technologies available to them. Doing so will help them develop a sound migration and cabling strategy.

Originally published at www.fiber-optic-cable-sale.com